skip to main |

skip to sidebar

Day 18,19,20 Fukushima 1 Nuclear Accidents

7:00 AM

Posted by Energetic

Fukushima 1 Nuclear Accident Day 18, 19, 20

Monday, 28 March

High levels of radiation from contaminated water hindered work on restoring the cooling pumps and other powered systems to reactors 1-4. The Japanese Nuclear Safety Commission reported that it assumed melted fuel rods in Unit 2 released radioactive substances into cooling water which subsequently leaked out through an unknown route to the Unit 2 turbine building basement.

In hopes of reducing the amount of water leaking, TEPCO reduced the amount of water pumped into Reactor 2 from 16 tons per hour to 7 tons per hour, despite the priority of cooling the reactor core. Confirming concerns, the temperature in the reactor raised by 20°C. Highly radioactive water was also found in three "trenches" (tunnels that house electrical wires from the turbines) which stretch toward, but do not connect to, the sea. Water levels in trenches of Units 2 and 3 were 1m below the level at which they would overflow to the sea, while the Unit 1 trench was 10cm from overflowing. TEPCO reported they used sandbags and concrete to prevent an overflow at the opening of the tunnel.

TEPCO confirmed finding low levels of plutonium in five samples from 21 March and 22 March, concluding that "two samples out of five may be the direct result of the recent incident."

Tuesday, 29 March

Unit 1 water injection is transfered from fire engine pumping to an emergency pump. Unit 4 control room power is restored, the final control room to receive power. Unit 2 and 3 water injection changes from salt water to freshwater. Radiation reaches the United Kingdom, with very low levels of radioactive iodine detected in Glasgow and Oxfordshire, although there is no evidence that this iodine is from Japan.

Wednesday, 30 March

Smoke escaped from the Fukushima II (Dai-ini) nuclear plant. Fukushima II plant is 6 miles from the Fukushima I (Dai-Ichi) facility, and was thought not to be at risk.

At Fukushima I, Japan's Nuclear and Industrial Safety Agency (JNISA) reiterated concerns about a unit 3 breach on 30 March. NHK World reported the JNISA's concerns as "air may be leaking," very probably through "weakened valves, pipes and openings under the reactors where the control rods are inserted," but that "there is no indication of large cracks or holes in the reactor vessels." Plans were announced to spray debris at the Fukushima plant with a water-soluble resin to prevent further spread of radioactivity. The concentration of 131

I in seawater, 330 m south of the discharge canal of units 1 to 4 at 13:55, March 29th, 2011, was 130,000 Bq/l or 3,355 times the regulatory limit (the highest so far). The concentration of 134

Cs was 520 times the regulatory limit, while 137

Cs was 350 times the limit.

-

Nuclide Concentration (Bq/cm3) Regulatory limit (Bq/cm3) Concentration / Regulatory Limit 99m

Tc1.6×10−1 4.0×101 .04 131

I1.3×102 4.0×10−2 3250 134

Cs3.1×101 6.0×10−2 517 136

Cs2.8×100 3.0×10−1 9.3 137

Cs3.2×101 9.0×10−2 356 140

Ba5.0×100 3.0×10−1 17 140

La2.5×100 4.0×10−1 6.3

Ikata Nuclear Power Plant

6:53 AM

Posted by Energetic

The Ikata Nuclear Power Plant is a nuclear power plant in the town of Ikata in the Nishiuwa District in Ehime Prefecture, Japan. It is the only nuclear plant on the island of Shikoku. It is owned and operated by the Shikoku Electric Power Company.

The plant is on a site with an area of 860,000 m2 (212 acres). 47% of the site is green, compared to the other plants Yonden operates which are 13.8, 45.5, 20.1, and 21.2%.Reactors on site

| Unit | Reactor type | Capacity | First criticality | Commissioned | Type |

|---|---|---|---|---|---|

| Ikata - 1 | PWR | 566 MW | February 17, 1977 | September 30, 1977 | Mitsubishi 2-loop plant |

| Ikata - 2 | PWR | 566 MW | August 19, 1981 | March 19, 1982 | Mitsubishi 2-loop plant |

| Ikata - 3 | PWR | 890 MW | March 29, 1994 | December 15, 1994 | Mitsubishi/Westinghouse 3-loop plant |

Accidents

- On March 3, 2004 there was a coolant leak in Unit 3.

Technical achievements

- On August 13, 2003 The maximum burnup for spent fuel was changed from 48,000 MWd/ton to 55,000 MWd/ton.

- Ikata - 1 became the world's first all-in-one extraction of the core internals in a PWR. Mitsubishi Heavy Industries did replacement work of the upper and lower internals in order to accommodate more control rods and allow for higher fuel burnup.

- Ikata - 3 loaded a partial MOX fuel core for the cycle beginning February 24, 2010.

| Ikata Nuclear Power Plant | |

|---|---|

| Country | Japan |

| Construction began | September 1, 1973 |

| Commission date | September 30, 1977 |

| Operator(s) | Shikoku Electric Power Company |

| Reactor information | |

| Reactors operational | 2 x 566 MW 1 x 890 MW |

| Power generation information | |

| Annual generation | 12,925 GW·h |

| Net generation | 281,159 GW·h |

Indian Point Energy Center - IPEC

6:43 AM

Posted by Energetic

Indian Point Energy Center (IPEC) is a three-unit nuclear power plant station located in Buchanan, New York just south of Peekskill. It sits on the east bank of the Hudson River, 38 miles north of New York City. The power plant provides up to 30% of the electricity used by New York City and Westchester County.

The Indian Point Energy Center is owned and operated by Entergy Nuclear Northeast, a subsidiary of Entergy Corporation, and includes two operating Westinghouse pressurized water reactors – designated Indian Point 2 and Indian Point 3 – which Entergy bought from Consolidated Edison and the New York Power Authority respectively. The facility also contains the permanently shut down Indian Point Unit 1 reactor. Total employment at the site is 1,683.IPEC Reactor Unit 1

Indian Point Energy Center 1, built by Consolidated Edison, was the first of three reactors at this location. It was a 275-megawatt pressurized water reactor and was issued an operating license on March 26, 1962 and started operations on September 16, 1962. The first core at the Indian Point power station used a thorium-based fuel, but it did not live up to expectations. The plant was operated with uranium oxide fuel for the remainder of its operations.

The Unit 1 reactor was shut down on October 31, 1974 because the emergency core cooling system did not meet regulatory requirements. All spent fuel was removed from the reactor vessel by January 1976. The licensee, Entergy, plans to decommission Unit 1 with Unit 2.[6]

IPEC Reactor Units 2 and 3

The two additional reactors, Indian Point 2 and 3, were built in 1974 and 1976. Together they generate up to 30% of the electricity used in New York City, depending on a variety of conditions.

Spent fuel

Indian Point Energy Center stores used fuel rods in two spent fuel pools at the facility. According to the New York State Department of Environmental Conservation, the Indian Point spent fuel pools, which contain more nuclear material than the reactors, "have no containment structure". According to Jonathan Alter, the pools are located in bedrock, not above-ground as at many other plants including the Japanese ones. Indian Point began "dry casking" spent fuel rods in 2008, a "safer alternative". Some rods have already been moved to casks from the spent fuel pools, which will be kept "nearly full of spent fuel, leaving enough space to allow emptying the reactor completely should that become necessary."

Incidents

On October 17, 1981, 100,000 gallons of Hudson River water leaked into the Indian Point 2 containment building from the fan cooling unit, undetected by a safety device designed to detect hot water. The flooding, covering the first 9 feet of the reactor vessel, was discovered when technicians entered the building. Two pumps which should have removed the water were found to be inoperative. NRC proposed a $210,000 fine for the incident.

In 2005, Entergy workers while digging discovered a small leak in a spent fuel pool. Water containing tritium and strontium 90 was leaking through a crack in the pool building "and then finding its way into the nearby Hudson River." Workers were able to keep the fuel rods "safely covered" despite the leak. On March 22, 2006 the New York Times also reported finding radioactive nickel-63 and strontium in groundwater on site.

On April 23, 2007, the Nuclear Regulatory Commission fined the owner of the Indian Point nuclear plant $130,000 for failing to meet a deadline for a new emergency siren plan. The 150 sirens at the plant are meant to alert residents within 10 miles to a plant emergency.

On January 7, 2010, NRC inspectors reported that an estimated 600,000 gallons of mildly radioactive steam was intentionally vented after an automatic shutdown of Unit 2. The levels of tritium in the steam were below those allowable by NRC safety standards.

On November 7, 2010, an explosion occurred in the main transformer for Indian Point 2.

Safety

On March 10, 2009 the Indian Point Nuclear Power Plant was awarded the fifth consecutive top safety rating for annual operations by the Federal regulators. According to the Hudson County Journal News, the plant had shown substantial improvement in its "safety culture" in the previous two years.

Terrorism

Indian Point Energy Center is protected by federal, state, and local law enforcement agencies, including a National Guard base within a mile of the facility, as well as by private off-site security forces.

During the September 11 attacks, American Airlines Flight 11 flew near the Indian Point Energy Center en route to the World Trade Center. Mohamed Atta, one of the 9/11 hijackers/plotters, had considered nuclear facilities for targeting in a terrorist attack. Entergy says it is prepared for a terrorist attack, and asserts that a large airliner crash into the containment building would not cause reactor damage. Following 9/11 the NRC required operators of nuclear facilities in the U.S. to examine the effects of terrorist events and provide planned responses. In September 2006, the Indian Point Security Department successfully completed mock assault exercises required by the Nuclear Regulatory Commission. However, according to Riverkeeper, an environmental group, these NRC exercises are inadequate, because they do not envision a large enough group of attackers.

The New York State Department of Environmental Conservation states that the spent fuel pools at Indian Point are "exposed and unsecured" and therefore "vulnerable to attack". According to the New York Times, fuel stored in dry casks is "less vulnerable to terrorist attack than fuel in the storage pools".

Safety Procedures

A 2003 report commissioned by then Governor George Pataki concluded that the "current radiological response system and capabilities are not adequate to...protect the people from an unacceptable dose of radiation in the event of a release from Indian Point.”

Evacuation

The Indian Point Energy Center evacuation plan focuses "on a 10-mile ring populated by about 300,000 people." In the wake of the 2011 Japanese nuclear accidents, columnist Peter Applebome noted in The New York Times that a fifty mile radius from Indian Point (the area which the State Department suggested Americans avoid in Japan) "includes almost all of New York City except for Staten Island; almost all of Nassau County and much of Suffolk; all of Bergen County, N.J.; all of Fairfield, Conn.". He quotes Purdue University professor Daniel Aldrich: "“Many scholars have already argued that any evacuation plans shouldn’t be called plans, but rather ‘fantasy documents".

In an interview, Entergy executives said they doubt that the evacuation zone would be expanded to reach as far as New York City.

Earthquake risk

Researchers from Columbia University's Lamont-Doherty Earth Observatory have located a previously unknown active seismic zone running from Stamford, Connecticut, to the Hudson Valley town of Peekskill, New York - the Ramapo Fault - which passes less than a mile north of the Indian Point nuclear power plant. Indian Point was built to withstand an earthquake of 6.1 on the Richter scale, according to a company spokesman. Entergy executives have also noted "that Indian Point had been designed to withstand an earthquake much stronger than any on record in the region, though not one as powerful as the quake that rocked Japan".

Msnbc.com reports however that "Indian Point nuclear reactor No. 3 has the highest risk of earthquake damage in the country, according to new NRC risk estimates provided to msnbc.com." According to the report, the reason is that plants in known earthquake zones like California were designed to be more quake-resistant than those in less affected areas like New York.

NRC responded in a release that "The NRC results to date should not be interpreted as definitive estimates of seismic risk."

Recertification or closure

On May 2, 2007, the NRC announced that the "License Renewal Application for Indian Point Nuclear Plant is available for Public Inspection". This initiated Entergy's effort to extend the operating licenses of each unit by 20 years. The original federal licenses for the two reactors expire in 2013 and 2015.

On September 23, 2007, Friends United for Sustainable Energy (FUSE) filed legal papers with the NRC opposing the relicensing of the Indian Point 2 reactor. The group contends that the NRC improperly held Indian Point to less stringent design requirements. The NRC responds that the newer requirements were put in place after the plant was complete.

On December 1, 2007, Westchester County Executive Andrew J. Spano, New York Attorney General Andrew Cuomo, and New York Governor Elliot Spitzer called a press conference with the participation of environmental advocacy groups Clearwater and Riverkeeper to announce their united opposition to the re-licensing of the Indian Point nuclear power plants. The New York State Department of Environmental Conservation and the Office of the Attorney General requested a hearing as part of the process put forth by the Nuclear Regulatory Commission.] In September 2007 The New York Times reported on the rigorous legal opposition Entergy faces in its request for a 20-year licensing extension for Indian Point Nuclear reactor 2.

A water quality certificate is a prerequisite for a 20-year renewal by the NRC. On 3 April 2010 the Department of Environmental Conservation ruled that Indian Point violates the federal Clean Water Act, because "the power plant’s water-intake system kills nearly a billion aquatic organisms a year, including the shortnose sturgeon, an endangered species." The state is demanding Entergy construct new closed-cycle cooling towers, at a cost of over $1B, a decision that will effectively close the plant for nearly a year. Regulators denied Entergy's request to install fish screens that they said would improve fish mortality more than new cooling towers.

Advocates of recertifying Indian Point include New York City mayor Michael Bloomberg, who says that "Indian Point is critical to the city's economic viability".

As governor, Andrew Cuomo continues to call for closure of Indian Point. Several members of the House of Representatives representing districts near the plant have also opposed recertification, including Democrats Nita Lowey, Maurice Hinchey, and Eliot Engel and then Republican member Sue Kelly.

| Indian Point Energy Center | |

|---|---|

| Country | United States |

| Locale | Buchanan, New York |

| Status | Operational |

| Commission date | Unit 2: August 1, 1974 Unit 3: August 30, 1976 |

| Licence expiration | Unit 2: September 28, 2013 Unit 3: December 12, 2015 |

| Operator(s) | Entergy |

| Architect(s) | United Engineers and Constructors |

| Constructor(s) | United Engineers and Constructors |

| Reactor information | |

| Reactor type(s) | PWR |

| Reactor supplier(s) | Westinghouse |

| Power generation information | |

| Installed capacity | Unit 2: 1,020 MW Unit 3: 1,025 |

| Annual generation | Unit 2: 8,842 GWh Unit 3: 7,797 |

Millstone Nuclear Power Plant

10:30 AM

Posted by Energetic

The Millstone Nuclear Power Plant is the only nuclear power generation site in Connecticut. It is located at a former quarry (from which it takes its name) in Waterford. Of the three reactors built here, units two and three are still operating at a combined output rating of 2020 MWe.

Events and Nuclear Accident

The Millstone Nuclear Power Plant covers about 500 acres (2 km²). The power generation complex was built by a consortium of utilities, using Niantic Bay (which is connected to Long Island Sound and the Atlantic Ocean) as a source of coolant water.

Although located in Waterford, Millstone is most clearly seen from downtown Niantic. It is visible from the Niantic Boardwalk area and from the Niantic River Bridge, and is also visible to Amtrak customers on the NEC line which as it skirts Niantic Bay.

Millstone Nuclear Power Plant earned OSHA's top award for workplace safety on October 14, 2004, and earned the Top Industry Practice/ Framatone ANP Vendor Award for its work developing novel ultrasonic leak inspection techniques in March 2001.[2]

Millstone Nuclear Power Plant Units 2 and 3, both pressurized water reactors (one from Westinghouse and one from Combustion Engineering), were sold to Dominion by Northeast Utilities in 2000 and continue to operate.

On November 28, 2005, after a 22-month application and evaluation process, Millstone was granted a 20-year license extension to both units 2 and 3 by the NRC.Unit 1

Millstone 1 was a General Electric boiling water reactor, producing 660 MWe, shut down in November 1995 before being permanently closed in July 1998. On February 20, 1996 a leaking valve forced the shutdown of this unit, and unit 2; multiple equipment failures were found.

- Construction Permit Issued: May 19, 1966

- Final Safety Analysis Report (FSAR) Filed: November 1, 1968

- Provisional Operating License Issued: October 7, 1970

- Full Term Operating License Issued: October 31, 1986

- Full Power License: October 7, 1970

- Initial Criticality: October 26, 1970

- Synchronized to the Grid: November 1970

- Commercial Operation: December 28, 1970

- 100% Power: January 6, 1971

- Leaking valve forced shutdown multiple equipment failures detected: February 20, 1996

- Permanently Ceased Operations: July 21, 1998

Unit 2

Millstone 2 is a Combustion Engineering plant built in the 1970s, and has a maximum power output of 2700 MWth (870 MWe). It has 2 steam generators, and 4 reactor cooling pumps (RCP). It is currently undergoing an upgrade to its safe shutdown system which already met NRC standards. During its refueling outage in October 2006, the operator installed a new pressurizer.

- Construction Permit Issued: December 11, 1970

- Final Safety Analysis Report (FSAR) Filed: August 15, 1972

- Full Term Operating Licensing Issued: September 26, 1975

- Full Power License: September 26, 1975

- Initial Criticality: October 17, 1975

- Commercial Operation: December 26, 1975

- 100% Power: March 20, 1976

- “Stretch Power”: June 25, 1979

- Operating License Extension Requested: December 22, 1986

- Operating License Extension Issued: January 12, 1988

- Full Term Operating License Expires: December 11, 2010

- Operating License Expires: July 31, 2015

- Extended Operating License Expires: July 31, 2035

Unit 3

Millstone 3 is a Westinghouse plant that started operating in 1986, and has a maximum power output of 3411 MWth (1150 MWe). Recently, the NRC approved a power uprate for Unit 3 that will increase its electrical output 7.006% to 3650 MWth (1230 MWe. The increase will take effect by the end of 2008.

- Construction Permit Issued: August 9, 1974

- Initial Criticality: January 23, 1986

- Commercial Operation: April 23, 1986

- Operating License Expires: November 25, 2025

- Extended Operating License Expires: November 25, 2045

Events and Nuclear Accident

- On February 26, 1996, A leaking valve forced the shutdown of units 1 and 2, multiple equipment failures were found.

- On April 17, 2005, Millstone plant safely shut down without incident when a circuit board monitoring a steam pressure line short-circuited, which caused the board to malfunction and indicate an unsafe drop in pressure in the reactor's steam system, when in reality there was no drop in steam pressure. The cause was attributed to "tin whiskers". In response to this event, Millstone implemented a procedure to inspect for these whiskers at every refueling outage, or 18 months. David Lochbaum, a scientist affiliated with the Union of Concerned Scientists, while remaining critical of the processes leading to the discovery of the whiskers, praised Millstone for its handling of the situation.

- In September, 2009, unit-2 shut down when an electrical storm caused power fluctuations. When workers tried to restart the unit, they discovered a small leak in the reactor coolant pump.

- 12/21/2009 Millstone Unit 3 Reactor Trip and Shutdown Greater Than 72 Hours.

- 07/27/2009 Millstone Unit 2 Reactor Trip and Shutdown Greater Than 72 Hours

| Millstone Nuclear Power Plant | |

|---|---|

| Country | United States |

| Locale | Waterford, Connecticut |

| Status | Operational |

| Commission date | Unit 2: December 26, 1975 Unit 3: April 23, 1986 |

| Licence expiration | Unit 2: July 31, 2035 Unit 3: November 25, 2045 |

| Construction cost | Unit 2: $424 million Unit 3: $3.77 billion |

| Operator(s) | Dominion |

| Architect(s) | Unit 2: Bechtel Unit 3: Stone & Webster |

| Reactor information | |

| Reactor type(s) | PWR |

| Reactor supplier(s) | Unit 2: Combustion Engineering Unit 3:Westinghouse |

| Power generation information | |

| Installed capacity | Unit 2: 882 MW Unit 3: 1,155 |

| Annual generation | Unit 2: 7,686 GWh Unit 3: 8,699 |

Donald C. Cook Nuclear Power Plant

12:09 PM

Posted by Energetic

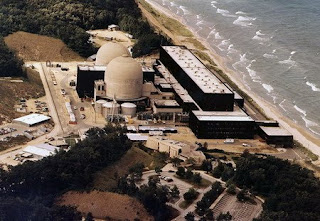

Donald C. Cook Nuclear Power Plant is a nuclear power plant located just north of the city of Bridgman, Michigan which is part of Berrien County, on a 650-acre (2.6 km2) site 11 miles south of St. Joseph, Michigan, USA. The plant is owned by American Electric Power (AEP) and operated by Indiana Michigan Power, an AEP subsidiary. This is currently the company's only nuclear power plant, which has two nuclear reactors. The plant is operated by the Indiana Michigan Power Company and owned by American Electric Power.

Built at a cost of $1.3 billion, the plant produces enough electricity to meet the needs of a city 1.25 million people.

The Donald C. Cook Nuclear Power Plant is connected to the power grid via one 765KV line that goes from the plant to AEP's DuMont substation near Lakeville, Indiana and by numerous 345KV lines, two of which interconnect with Consumers Energy/METC, connecting with the Palisades Nuclear Generating Station, owned by Entergy.

The plant has a visitors center that was open to the public six days a week on a drop in basis. Since the attacks of September 11, however, the plant is open only to school groups by reservation. The visitors center features a 26 foot animated model demonstrating how the plant operates.

Nuclear Power Plant Incidents

- A transformer caused an automatic shutdown of Unit 1 in 2003.

- A massive intrusion of fish caused both units to shut down for approximately 25 hours on April 24–25, 2003.

- A fire broke out in the generator of Unit 1 on September 20, 2008. causing the reactor to shut down. No radiation was released and Unit 2 continued to operate at full power

| Unit 1 | Unit 2 | |

|---|---|---|

| Reactor Type | Pressurized Water | Pressurized Water |

| Reactor Manufacturer | Westinghouse | Westinghouse |

| Turbine Manufacturer | General Electric | Brown Boveri |

| Generation Capacity | 1,020 megawatts | 1,090 megawatts |

| Transmission System Connection | 345,000 volts | 765,000 volts |

| Construction Began | March 1, 1969 | March 1, 1969 |

| Grid connection | February 10, 1975 | March 22, 1978 |

| Operational Date | August 27, 1975 | July 1, 1978 |

| Expiration of Original License | October 25, 2014 | December 23, 2017 |

| Expiration of Renewed License | 2034 | 2037 |

Bellefonte Nuclear Power Plant

6:27 AM

Posted by Energetic

Bellefonte Nuclear Power Plant owned by the Tennessee Valley Authority is located in Hollywood, Alabama.

The two partially-built 1,256 megawatt (MWe) pressurized water reactors on the site were made by Babcock and Wilcox and are called a 205 design due to the number of fuel assemblies in the core. These units are of the same design as WNP-1 which is also unfinished, and as the Mulheim Karlich A reactor in Germany that operated for three years and proved the design. Unit 1 was 88% complete and Unit 2 was 58% when development was suspended in 1988 after a $6 billion investment. Subsequent asset recovery activities, along with more recent inspections of remaining equipment, resulted in BLN 1&2 now being considered approximately 55 percent and 35 percent complete, respectively. Although the construction permits were terminated on September 15, 2006, TVA is investigating completion of these first two units with operation projected to start Unit 1 in 2017 and Unit 2 in 2021. In August 2008 TVA asked the NRC to reinstate the construction permits as part of the restart evaluation. This request was granted by the NRC on February 9, 2009, albeit as a terminated application which required significant inspection of all systems to bring the license to the deferred stage. The status was upgraded January 14, 2010 to deferred.

On September 22, 2005 it was announced that Bellefonte was also selected as the site for one or two AP1000 pressurized water reactors to be called Units 3 and 4. TVA filed the necessary applications in November 2007 to begin the design and construction process. For details, see Nuclear Power 2010 Program.

In August 2009, the Tennessee Valley Authority, faced with "falling electric sales and rising costs from cleaning up a massive coal ash spill in Tennessee", trimmed plans for the potential four-unit Bellefonte nuclear plant to one reactor.

On August 20, 2010 the TVA Board of Directors authorized $248 million to continue development of the Bellefonte Unit 1. Construction is expected to resume in 2011.

The rough estimate to complete BLN 1 by itself is between $4.2 and $4.8 billion in 2010 dollars.

| Bellefonte Nuclear Generating Station | |

|---|---|

| Country | United States |

| Locale | Hollywood, Alabama |

| Status | Proposed |

| Construction cost | US$6 billion (Units 1 & 2) |

| Owner(s) | Tennessee Valley Authority |

| Reactor information | |

| Reactors planned | 2 x 1,100 MW |

| Reactor type(s) | Pressurized water reactor |

| Reactor supplier(s) | Babcock and Wilcox |

Bell Bend Nuclear Power Plant Project

6:26 AM

Posted by Energetic

The Bell Bend Nuclear Power Plant Project is a prospective nuclear power plant which may be built on the Bell Bend of the Susquehanna River in Luzerne County, Pennsylvania, near the Susquehanna Steam Electric Station.

On October 10, 2008, Pennsylvania Power and Light (PPL) filed an application for a Combined Construction and Operating License (COL) for the plant with the Nuclear Regulatory Commission (NRC) by the end of 2008 — in time for the potential plant to qualify for production tax credits under the U.S. Energy Policy Act of 2005.[2] NRC review of the 10,000-page COLA is expected to take three to four years.

Bell Bend would use the 1,600 MWe European Pressurized Reactor (EPR) designed by the French company AREVA. Plants using this technology now are under construction in Finland, France, and China. The plant would be built by PPL and UniStar Nuclear Energy, a joint enterprise of Constellation Energy and French energy giant EDF.

PPL spokesman Dan McCarthy said the plant would cost about $10 billion to develop, and seven to eight years to construct — beginning operation in 2016 or 2017. A later estimate gives costs as $13–15 billion and an operational starting date of 2018-20. PPL filed an initial application for federal loan guarantees by the September 29, 2008 deadline. PPL intends to submit the second part of the application by the December 19 deadline. PPL Chief Operating Officer William Spence said, "Without federal loan guarantees, companies like PPL will not be able to secure financing for the substantial cost of building new, advanced-design nuclear energy plants that will help this country achieve challenging limits on carbon dioxide emissions, as well as energy independence".Victoria County Nuclear Power Plant Project

6:24 AM

Posted by Energetic

The Victoria County Nuclear Power Plant Project is a proposed two-unit nuclear power plant, in Victoria County, Texas. If built, the facility would occupy an 11,500-acre (47 km2) site in McFaddin, an unincorporated community south of Victoria. Plant structures would occupy about 300 acres (120 ha) and a man-made lake for plant cooling would cover about 4,900 acres (20 km2).

Exelon filed the Combined Construction and Operating License (COL) application for the plant on September 3, 2008 with the Nuclear Regulatory Commission (NRC). Originally, the plant would have had two GE–Hitachi Economic Simplified Boiling Water Reactors (ESBWRs) which between them would generate over 3,000 MWe. The model is currently in the process of design certification by the NRC. The application reportedly cost $23 million to prepare and file.

Exelon later decided to change reactor design, choosing the established GE 1,350 MWe Advanced Boiling Water Reactor (ABWR) instead, which is also to be built at the South Texas Project.

In July 2009, Exelon announced that it was suspending its COL application. "We are not leaving Victoria," said Exelon's Thomas O'Neill, "But today's economic realities compel us to defer any decision on construction for a while." Exelon will continue to pursue the Early Site Permit (ESP) for the station, under which the NRC would certify that the site meets the criteria of site safety, environmental impact, and emergency planning.

In March 2010, Exelon announced that it was formally withdrawing its COL application, while submitting its application for an early site permit (ESP). The NRC's review of the ESP application is expected to take three to four years. If Exelon later decides to revisit the project, having the ESP in hand would simplify and shorten the licensing procedure.Levy County Nuclear Power Plant Project

6:22 AM

Posted by Energetic

The Levy County Nuclear Power Plant Project is the umbrella term for a proposed nuclear power plant in Levy County, Florida. Proposed in 2006, Progress Energy Florida (PEF) announced the selection of 5,100 acres (21 km2) in southern Levy County for the potential construction of nuclear reactors. The site's proximity to the company's existing Crystal River 3 Nuclear Power Plant will provide opportunities for efficiencies in shared support functions at both facilities.

Progress Energy Florida submitted a filing with the Florida Public Service Commission (PSC) on March 11, 2008, outlining its need for additional electricity and proposing to meet that need with two nuclear units in Levy County. The PSC scheduled hearings on the project in late May, and approved it in July. The company then applied for a Combined Construction and Operating License (COL) from the Nuclear Regulatory Commission (NRC) on July 30, 2008. Costs of the two nuclear units are estimated at $14 billion, plus $3 billion for necessary transmission upgrades.

On October 14, 2008, the PSC voted to allow PEF to charge customers an additional $11.42 per 1,000 kW·h, beginning in January 2009, to pay for the Levy plant and work upgrading the Crystal River plant.

On January 5, 2009, PEF awarded an engineering, procurement, and construction (EPC) contract to Westinghouse and The Shaw Group's nuclear division to build the two reactors for $7.65 billion. The reactors were supposed to be operational by 2016–18. In May, after the NRC denied permission to begin excavation work on the site to prepare for construction prior to issuing the COL, Progress Energy announced that commercial operation of the two new reactors had been pushed back "a minimum of 20 months." In view of the delay, Progress Energy has requested approval from the Public Service Commission to reduce the project cost to consumers in 2010 from $12.63 to $6.69 per 1000 kW·h.

On August 11, 2009, Florida governor Charlie Crist and his cabinet unanimously adopted the recommendation of the state Department of Environmental Protection, and approved the plant's Site Certification Application (SCA). Site certification is the last major state-level approval needed before Progress can start constructing the Levy plant. The approval included a requirement that Progress shut down coal-fired electrical generating units 1 & 2 at its nearby Crystal River Energy Complex by the end of 2020, assuming the timely licensing and construction of the Levy nuclear power plant.| Levy County Nuclear Power Plant | |

|---|---|

| Country | United States |

| Locale | Levy County, Florida |

| Status | Proposed |

| Construction cost | $17 billion (approximately, including $3 billion for transmission lines) |

| Owner(s) | Progress Energy, Inc. |

| Reactor information | |

| Reactors planned | 2 x 1,105 MW |

| Reactor type(s) | AP1000 pressurized water reactors |

| Reactor supplier(s) | Westinghouse |

| Power generation information | |

| Installed capacity | 2,210 MW |

William States Lee 3 Nuclear Generating Station

6:20 AM

Posted by Energetic

The William States Lee 3 Nuclear Generating Station is a planned two-unit nuclear power plant. Duke Energy filed the Combined Construction and Operating License (COL) application for the plant on December 13, 2007 to the NRC. With this application, Duke Energy was the fourth company to apply for a license under the new procedure, and the license will be modeled after the Bellefonte NPP application that was filed by NuStart Energy two months prior, which is possible because both plants will use the AP1000 standard design. Duke expects to receive the COL for Lee in 2012. The first unit could come on line about 2016-2018.

The plant is named for William States Lee 3 (1929–1996), former chief executive officer (CEO) of Duke Energy (1982–94). This site will be adjacent to the Cherokee Nuclear Power Plant site which was never completed and abandoned in the early 1980s, and used by James Cameron as a film set for the 1989 movie The Abyss.

In December 2007, Duke Power announced that it would spend $160 million in 2008 on the plant and that total costs could range 5–6 billion dollars. In November 2008, Duke estimated the overnight cost of the plant at $11 billion.

| William States Lee III Nuclear Generating Station | |

|---|---|

| Country | United States |

| Locale | Cherokee County, near Gaffney, South Carolina |

| Construction cost | $11 billion (estimate) |

| Owner(s) | Duke Energy |

| Reactor information | |

| Reactors planned | 2 x 1117 MW |

| Reactor type(s) | AP1000 |

| Reactor supplier(s) | Westinghouse |

Galena Nuclear Power Plant Project

6:18 AM

Posted by Energetic

The Galena Nuclear Power Plant Project is a proposed nuclear power plant to be constructed in the Yukon River village of Galena in the U.S. state of Alaska. If built, it would be the first non-military nuclear power plant built in Alaska to be utilized for public utility generation.

Galena is not accessible by road, and its energy needs are provided by large air and water shipments of fuel oils, gasoline and propane. Electricity use is avoided, and accounts for only 4% of the village's energy usage. Space heating is done by the end user by using kerosene and wood. Because of Galena's climate the Yukon River is frozen 8–9 months of the year, stopping all delivery by the seasonal river barges. The alternative delivery is by aircraft tanker. This scarcity of fuel makes energy very expensive for area residents. The price of electricity is dictated by the price of fuel oil, $2.45/gal = $0.35/kWh(2004), $4.25/gal = $0.68/kWh(2006).

Galena is not accessible by road, and its energy needs are provided by large air and water shipments of fuel oils, gasoline and propane. Electricity use is avoided, and accounts for only 4% of the village's energy usage. Space heating is done by the end user by using kerosene and wood. Because of Galena's climate the Yukon River is frozen 8–9 months of the year, stopping all delivery by the seasonal river barges. The alternative delivery is by aircraft tanker. This scarcity of fuel makes energy very expensive for area residents. The price of electricity is dictated by the price of fuel oil, $2.45/gal = $0.35/kWh(2004), $4.25/gal = $0.68/kWh(2006).

On December 14, 2004, the Galena City Council accepted a proposal from Toshiba to test their new 10 megawatt Toshiba 4S (Super Safe, Small and Simple) “nuclear battery” reactor design, which would require only minimal staffing. If the reactor is successfully licensed, Toshiba will install it free of charge by 2012. It is expected to provide electricity for $0.05–$0.13/kWh, which factors in only operating costs. On paper, it has been determined that the reactor could run for 30 years without refueling.

The liquid sodium cooled reactor would heat steam to 500 °C (932 °F) and would be located in a sealed concrete cylindrical vault 30 m (98 ft) underground, while the above-ground turbine building would be 22 × 16 × 11 m (72 × 52.5 x 36 ft) in size. The generation plant would provide a more-than-sufficient ten megawatts of power to the community of Galena.

Toshiba intends to sell more 4S reactors in Alaska and the rest of the United States if the Galena project succeeds.

As of 2010, the project is still in its final planning stages with final regulatory submission planned for October 2010. The City Council passes a resolution every six months reaffirming the community's support for the reactor.

Day 15,16,17 Fukushima 1 Nuclear Accidents

5:54 AM

Posted by Energetic

Fukushima 1 Nuclear Accident Day 15, 16, 17

Friday, 25 March

Units 1, 2 and 3 had possible breaches in their containment vessels. NISA announced that a breach had likely occurred in the containment vessel of the unit 3 reactor, the only one using a plutonium fuel mix (MOX). Officials suspected it was leaking radiation. Kyodo News reported highly radioactive water was found in the turbine buildings of unit 1 and 2.

US Navy began the transport by barge of 1,890 cubic meters (500,000 gallons) of fresh cooling water to the Fukushima reactors. This fresh water supply is expected to arrive on site within two days.

Japan announced transportation would be provided in a voluntary evacuation zone of 30 kilometres (19 mi).

Tap water was reported to be safe for infants in Tokyo and Chiba but still exceeded limits in Hitachi and Tokaimura.

An analysis of stagnant water in the basement floor of the turbine building of Unit 1 showed heavy contamination.

-

Nuclide Concentration (Bq/ml) 38

Cl1.6×106 74

As3.9×102 91

Y5.2×104 131

I2.1×105 134

Cs1.6×105 136

Cs1.7×104 137

Cs1.8×106 140

La3.4×102

Saturday, 26 March

Replacing seawater with fresh water for cooling became a priority due to worries that the salt in the seawater was clogging pipes and coating fuel rods, which may have been hindering the cooling process.

It was reported that radiation levels in water in the unit 2 turbine room measured 1 Sv/h, or 10 million times the normal radioactivity of water circulating in an operating reactor, and four times the yearly level allowed for workers. This has since been denied by Japanese officials as a misread by one of the employees working inside the plant, prompting all of the workers to flee before a second reading could be taken to confirm.

Sunday, 27 March

The IAEA announced that workers hospitalized for treatment of radiation burns on Friday had been exposed to between 2 and 6 Sv of radiation at their ankles when standing in water in unit 3.

TEPCO reported measurements of very high radiation levels of 1000 mSv/hr in the basement of the unit 2 turbine building, which officials reported was 10 million times higher than what would be found in the water of a normally functioning reactor. Hours into the media frenzy, the company retracted its report and stated that the figures were not credible. "because the level was so high the worker taking the reading had to evacuate before confirming it with a second reading." Shortly following the ensuing wave of media retractions that discredited the report worldwide, TEPCO clarified its initial retraction; the radiation from the pool surface in the basement of the unit 2 turbine building was found to be "more than 1,000 millisieverts per hour," as originally reported, but the concentration of radioactive substances was only 100,000 times higher than usual, not 10 million. The high radiation levels delayed technicians working to restore the water cooling systems for the troubled reactors.

Japan's Nuclear and Industrial Safety Agency indicated that "The level of radiation is greater than 1,000 millisieverts. It is certain that it comes from atomic fission. But we are not sure how it came from the reactor."

The IAEA reported temperatures at the bottom of the Reactor Pressure Vessel (RPV) at Unit 2 fell to 97 °C from 100 °C on Saturday. Water is being pumped from the turbine hall basement to the condenser in order to allow power restoration activities to continue.

New aerial video recorded on 27 March by a Ground Self-Defense Force helicopter revealed the clearest and most detailed view of the damaged plant to date. Significant observations included:

- White vapor, possibly steam, emanating from the buildings of reactors 2, 3, and 4.

- The roof of the reactor 2 building has been badly damaged but is still intact.

- The reactor 3 building is largely uncovered, its roof blown off in a hydrogen explosion over two weeks prior.

- The walls of the reactor 4 building have also collapsed.

Comanche Peak Nuclear Generating Station

3:16 AM

Posted by Energetic

Comanche Peak Nuclear Generating Station is located in Somervell County, Texas. The nuclear power plant is located 40 miles (65 km) southwest of Ft. Worth and about 60 miles (100 km) southwest of Dallas. It relies on nearby Squaw Creek Reservoir for cooling water. The plant has about 1,300 employees and is operated by Luminant Generation, a subsidiary of Energy Future Holdings Corporation.

Construction of the two Westinghouse pressurized water reactors began in 1974. Nuclear Reactor Unit 1, originally rated at 1,084 MWe, came online on April 17, 1990. Its current, 40-year operating license is valid until February 8, 2030. Unit 2, 1,124 MWe, followed on April 6, 1993 and is licensed to operate until February 2, 2033 when it has to renew its license. As of 2006[update] Unit 2 was the second-last power reactor to come online in the USA, followed only by Watts Bar 1.

In June 2008, the U.S. Nuclear Regulatory Commission (NRC) approved a request to increase the generating capacity of units 1 and 2 by approximately 4.5% each. Luminant Generation Co. implemented the changes during refueling outages. Unit 1 was uprated in autumn 2008 with a capacity increase of approximately 1,210 to 1,259 MWe and Unit 2, the capacity of which rose from an estimated 1,208 to 1,245 MWe, was uprated in autumn 2009.On September 19, 2008, Luminant filed an application with the NRC for a Combined Construction and Operating License (COL) for two new reactors. The reactor design selected is the US version of the 1,700 MWe Advanced Pressurized Water Reactor (US-APWR), developed by Mitsubishi Heavy Industries (MHI). The project is a joint venture, with Luminant owning 88 percent and 12 percent owned by MHI. Luminant did not release an estimate of the project's cost, but CEO David Campbell said Luminant would try to build its new reactors at the low end of current industry estimates, which he said range from $2,500 to $6,000 a kilowatt — $8.5 billion to $20.4 billion for a 3,400 MW plant.

Some environmental and anti-nuclear organizations and individuals oppose the plant expansion, citing environmental, public safety and cost concerns. These include the Sustainable Energy and Economic Development Coalition, Public Citizen and state Rep. Lon Burnam.| Comanche Peak Nuclear Power Plant | |

|---|---|

| Country | United States |

| Locale | Somervell County, near Glen Rose, Texas |

| Status | Operational |

| Construction began | 1974-93 |

| Commission date | Unit 1: April 17, 1990 Unit 2: April 6, 1993 |

| Licence expiration | Unit 1: February 8, 2030 Unit 2: February 2, 2033 |

| Operator(s) | Luminant Generation Co. |

| Reactor information | |

| Reactors operational | Unit 1: 1084 MW Unit 2: 1124 MW |

| Reactors planned | 2 x 1700 MW |

| Reactor type(s) | pressurized water reactor |

| Reactor supplier(s) | Westinghouse |

Cernavodă Nuclear Power Plant

3:09 AM

Posted by Energetic

The Cernavodă Nuclear Power Plant (Centrala Nucleară de la Cernavodă) is the only nuclear power plant in Romania. It produces around 20% of the country's electricity. It uses CANDU reactor technology from AECL, using heavy water produced at Drobeta-Turnu Severin as its neutron moderator and water from the Danube – Black Sea Canal for cooling.

By using nuclear power, Romania is able to reduce its greenhouse gas emissions by over 10 million tonnes each year.

The power plant was designed in Canada by Atomic Energy of Canada Limited in the 1980s, during the Communist era. The initial plan was to build five units.

Units 1 and 2 are currently fully operational. Three more partially-completed CANDU reactors exist on the same site, part of a project discontinued at the close of the Nicolae Ceauşescu regime. Units 3 and 4 are in their planning stages, with expected completion dates of 2014 and 2015 respectively.

CNE-INVEST is responsible for the preservation of Units 3-5.

Cernavoda Nuclear Reactor Unit 1

Unit 1, a CANDU 6-type, was finished in 1996 and produces 705.6 MW of electricity.

It was commissioned and began operating at full power in 1996 and has had record capacity factors of 90 per cent since 2005.

Cernavoda Nuclear Reactor Unit 2

A consortium of AECL and Ansaldo Nucleare of Italy, along with the Nuclearelectrica (SNN) SA, Romania’s nuclear public utility, was contracted in 2003 to manage the construction of the partially completed Unit 2 power plant and to commission it into service.

Four years later, Unit 2, another CANDU 6-reactor, achieved criticality on 6 May 2007 and was connected to the national grid on 7 August. It began operating at full capacity on 12 September 2007, also producing 706MW.

Unit 2 was officially commissioned on Friday, October 5, 2007 during ceremonies attended by Romanian Prime Minister Călin Popescu-Tăriceanu and senior officials from Atomic Energy of Canada Limited (AECL). This makes CNE-Cernavoda Station the largest power producer in the country.

Future expansion

Cernavoda Nuclear Reactor Units 3 and 4

Units 3 and 4 are expected to be CANDU 6 reactors with a similar design to Unit 2 and will each have a capacity of 740 MW. Units 3 and 4 are expected to be operational by 2016-2017. The project is estimated to take up to six years after the contracts are signed.

In a feasibility study carried out by Deloitte and Touche, the most economically viable scenario would be to build the two phases at the same time, with the cost estimated at €2.3 billion.

On 20 November 2008, Nuclearelectrica, ArcelorMittal, ČEZ, GDF Suez, Enel, Iberdrola and RWE agreed to set up a joint company dedicated to the completion, commissioning and operation of Units 3 and 4. The company named Energonuclear was registered in March 2009.

20th of January 2011, GDF Suez, Iberdrola and RWE pulled out of the project, following ČEZ which already left last September, citing "Economic and market-related uncertainties surrounding this project, related for the most part to the present financial crisis, are not reconcilable now with the capital requirements of a new nuclear power project".

Cernavoda Nuclear Reactor Units 5

There are currently no plans to complete Unit 5 at this time. However, the possibility of finishing construction remains.

Accidents and major events in Cerdanova Nuclear Power Plant

- On 30 May 2009, Unit 1 of the Romania's Cernavoda NPP was shut down following a water pipe crack. The Cernavoda NPP's second unit was undergoing an overhaul, so it was not producing any electricity.

- On 8 Apr 2009, the second reactor of the Romania's Cernavoda NPP was shut down due to a malfunction which led to electrical outages.

- On Jan 16 2010, the first unit was shut down due to steam leakage.

- On Jan 8 2011, the first unit was shut down for maintenance activities for a period of 48 hours.

| Cernavodă Nuclear Power Plant | |

|---|---|

| Country | Romania |

| Construction began | 1980s |

| Commission date | 2 December 1996 |

| Operator(s) | Nuclearelectrica |

| Reactor information | |

| Reactors operational | 2 x 700 MW |

| Reactors planned | 2 x 750 MW |

| Power generation information | |

| Annual generation | 5,178 GW·h |

| Net generation | 51,045 GW·h |

Leibstadt Nuclear Power Plant

6:08 AM

Posted by Energetic

The Leibstadt Nuclear Power Plant is located in the municipality Leibstadt (canton Aargau, Switzerland) on the Rhine River close of the Aare delta and the German border. It is so far the last nuclear power station built in Switzerland.

A boiling water reactor built there by the company General Electric with 1,220 MW of electrical power serves the power demands of the area, the cooling is done via a cooling tower. The nuclear power station has produced approximately 8.5 TWh per year, slightly less than the power station Gösgen.

The Leibstadt Nuclear Power Plant is owned by Leibstadt AG (KKL), which is composed of six Swiss energy companies: the Aare Tessin AG for electricity (Atel) with 27%, the northeast power stations AG (NOK) with 23%, the central-Swiss power stations AG (CKW) with 14%, the electricity company running castle AG (EGL) with 16%, the Bern power stations AG (BKW FMB energy AG) with 10% and the Aargauer of power stations AG (AEW energy AG) with 5 %. The management was originally done by the EGL, but with establishment of the Axpo it was consolidated within the Axpo group, so whereby today the NOK is the manager. The plant also houses a 380 kV switchyard for Beznau.

The Leibstadt Nuclear Power Plant is an old project, planning began 1964 for a 600 MW reactor with river water cooling. With the prohibition of the river water cooling by the Swiss Federal Council in 1971 a cooling tower solution was favored. In the further planning process the output was increased to 600 and then 900 MW. In 1984 the plant started after an eleven-year construction period. After the Three Mile Island accident in the year 1979 new safety regulations were implemented, and the completion was delayed several years. While the budget was originally set for 2,000,000,000 Swiss francs, and the end of construction it had amounted to over 5,000,000,000 francs.

The history of the completion of the KKL reflected increasingly critical attitudes toward Nuclear power in Switzerland during the 1970s and 1980s, which culminated in the resistance the Kaiseraugst Nuclear Power Plant.

| Leibstadt Nuclear Power Plant | |

|---|---|

| Country | Switzerland |

| Construction began | 1972 |

| Commission date | May 24, 1984 |

| Operator(s) | Kernkraftwerk Leibstadt AG |

| Reactor information | |

| Reactors operational | 1 x 1220 MW |

| Power generation information | |

| Annual generation | 9367 GW·h |

| Net generation | 174,091 GW·h |

Laguna Verde Nuclear Power Plant (LVNPP)

6:04 AM

Posted by Energetic

Laguna Verde Nuclear Power Plant (LVNPP) is located on the coast of the Gulf of Mexico, in Alto Lucero, Veracruz, Mexico. It is the largest electric power generating nuclear plant in Mexico by power generation and produces about 4.5% of the country's electrical energy. LVNPP has an original installed capacity of 1,365 Megawatts (Mw). It consists of two units General Electric Boiling Water Reactors (BWR-5) using Uranium (U235 Isotope 3% enriched) as fuel. Unit-1 (U-1) started its operation on July 29, 1990. Unit-2 (U-2) started its operation on April 10, 1995. The plant is owned and operated by Comisión Federal de Electricidad (CFE), the national electric company owned by the Mexican government.

Laguna Verde Nuclear Power Plant (LVNPP) has been considered a strategic facility for Sistema Eléctrico Nacional (SEN/National Power System), due to its high power generation capacity, lowest operating cost, and frequency and voltage regulation capacity. All the electric power generated is delivered to its single client: Centro Nacional de Control de Energía (CENACE/National Energy Control Center). CENACE is entrusted with the function of planning, directing, and supervising the transmission and distribution of electric power to end user. CENACE has classified LVNPP as Base Load Power Plant since the beginning of its operations.

The annual generation average for LVNPP in the last 5 years has been of 10,479 GWh, electric power sufficient to meet the demand of more than 4 million inhabitants.

Description

The generation of electric power at the CLV is based on the technology of nuclear fission of Uranium atoms, which takes place in the reactor. The energy released by the nuclear fission is transferred as heat from the fuel to the cooling water, which boils into steam. The quality of steam is controlled through a separator and dryer. The separator and dryer are part of the internal processes of the reactor pressure vessel. Power from each reactor is 3,944 Kilotons/Hour (Kt/h) of steam to generate 682 MW of electric power. Both Reactor Units (U1 and U2) operate using 444 enriched Uranium assemblies, storing power equal to 38.9 million oil barrels. This nuclear fuel is specifically designed to be admitted into the core of the reactor. The fuel is purchased only from qualified vendors worldwide.

After 18 months of operation, between 25% and 30% of the nuclear fuel is replaced. This activity is called "Refueling Outage" process. The turbine transforms power from steam (kinetic energy) into mechanical energy causing an electric generator to move (electric power production). Once the steam has gone through the turbine, it is cooled in a condenser; the water obtained in this manner is pumped again toward the nuclear reactor, to restart the generation cycle.

| Laguna Verde Nuclear Power Plant | |

|---|---|

| Country | |

| Locale | Alto Lucero, Veracruz Mexico |

| Status | Operational |

| Commission date | 1990 (Unit 1) 1995 (Unit 2) |

| Owner(s) | Mexican Government |

| Operator(s) | Comisión Federal de Electricidad (CFE) |

| Reactor information | |

| Reactors operational | 2 reactors |

| Reactor type(s) | Boiling Water Reactors (BWR-5) |

| Reactor supplier(s) | General Electric (GE) |

| Power generation information | |

| Installed capacity | 1,365 MW |

| Annual generation | 4.782 GW-h x 2 |

Power Uprate

In 2007 CFE signed a contract with an investment of $600 million USD to increase the original capability of each of the units of Laguna Verde by 20%, equivalent to 255 MW, in order to tend the growth of the demand of electric power in Mexico. This power uprate will allow to LVNPP an additional annual generation of 2,122 GWh, equivalent to the demand of a city of 800 thousand inhabitants.

General Electric performed the engineering analysis to determine the necessary plant modifications and to support the safety analysis report necessary for approval of the power uprate by the Mexican nuclear regulator Comisión Nacional de Seguridad Nuclear y Salvaguardias (CNSNS/National Commission on Nuclear Safety and Safeguards).

Work began in 2008 by Iberdrola and Alstom and is expected to finish late 2010. The main modifications consist in a turbine and condenser retrofit and the replacement of the electric generator, main steam reheater and the feedwater heater. The budget for the project is $605 million dollars.

Awards

Laguna Verde Nuclear Power Plant (LVNPP) has been recognized worldwide because of its performance, competitiveness, safety, reliability, environmentally friendly, innovations and continuous improvement. To support the nuclear option in Mexico, Laguna Verde has obtained several achievements, for example, National Quality Award (IFCT 2007), and Golden Award from Iberoamerican Foundation for Quality Management (FUNDIBEQ 2009).

In 2009, Laguna Verde obtained Annual recognition as a Enterprise Social Responsibility awarded by the Mexican Centre for Philanthropy.

The following table shows the chronologic developments at Laguna Verde.

| YEAR | EVOLUTION |

|---|---|

| 1976 | Implementation of the Quality Assurance Program as part of the international nuclear standard during the construction phase |

| 1982 | Implementation of the Quality Assurance Program in the operation phase |

| 1990 | Start of Reactor Unit 1 commercial operation |

| 1991 | World record broken for reaching 250 days of continuous operation (without interruptions) during the first generation cycle |

| 1995 | Start of Reactor Unit 2 commercial operation |

| 1995 | Laguna Verde used as a base to institutionalize the Total Quality program at the Comisión Federal de Electricidad (CFE) nationwide |

| 1995 | Accreditation of the Environmental Engineering Laboratory by the Mexican Accrediting Entity |

| 1997 | For the first time, CFE awards the Total Quality institutional prize, won by the Laguna Verde |

| 1997 | ISO 9001:1994 quality standard certification is obtained as part of the Continuous improvement program |

| 1999 | ISO 14001 quality standard certification was obtained |

| 1999 | Power generation boosted by 5% (sufficient to satisfy the needs of 200,000 persons) |

| 2002 | Certification in the Mexican Industrial Safety Standard NMX-SAST-001-IMNC-2000, which is the equivalent of the international OSHAS-18000. |

| 2003 | Certification in the ISO 9001:2000 Quality Standard based on process management. |

| 2004 | Laguna Verde reached Level-3 in the WANO excellence rating (maximum 1, minimum 5) |

| 2004 to 2007 | CLV significantly reduced the duration of refueling outage periods to 27 days |

| 2005 | Prize for the Nuclear Power Station with the best performance outside the USA given by WANO/ATLANTA |

| 2005 | Approval of the Extended Power Uprate Project (EPU) with an investment of $600 million USD, which will make it possible to increase the installed capacity by 20% compared with the original and which is strategically important to extend the station's useful life up to 50 years |

| 2006 and 2008 | Clean Industry biennial certification issued by the Mexican government through the Federal Environment Protection Agency as a result of complying with the 66 environment and safety standards |

| 2006 | Laguna Verde reached Level-2 in the WANO excellence rating, the highest level obtained by a nuclear power station outside the United States according to WANO/ATLANTA |

| 2006 | Recognition for world-class operation performance in Reactor Units 1 and 2 granted by General Electric |

| 2006 | Accreditation of the Metrology Laboratory by the Mexican Accrediting Entity |

| 2007 | Environmental Excellence Recognition (the highest award for the environment) obtained by the Mexican government because of high sustainability in the preservation of natural resources |

| 2008 | Laguna Verde obtains National Quality Prize 2007, which the highest recognition for policy and strategy quality and execution in congruence with the competitiveness and sustainability results obtained |

| 2008 to 2009 | Annual recognition as a Enterprise Social Responsibility awarded by the Mexican Centre for Philanthropy in compliance with ethical values, community support and respect and care for the environment |

| 2009 | Iberoamerican Quality Prize 2009 obtained, the highest award given by the Fundación Iberoamericana para Gestión de la Calidad (FUNDIBEQ/Iberoamerican Quality Management Foundation) |

| 2010 | Laguna Verde Manager receives the Nuclear Excellence Recognition delivered by WANO during Biennial Meeting, for promoting leadership that makes an extraordinary contribution to the promotion of Safe Operation Excellence at nuclear power stations |

Subscribe to:

Posts (Atom)